PREFACE • vii

1 THE DC SHUNT MOTOR • 1

2 THE DC SERIES MOTOR • 19

3 DC COMPOUND MOTORS • 25

4 SUMMARY REVIEW OF UNITS 1–3 • 33

5 STARTING AND OPERATING DC MOTORS • 37

6 ELECTRONIC DC MOTOR CONTROL • 47

7 DC VARIABLE SPEED MOTOR CONTROL • 63

8 DC MOTOR DYNAMIC BRAKING • 77

9 BASIC PRINCIPLES OF AUTOMATIC MOTOR

CONTROL • 85

10 ELECTROMECHANICAL AND SOLID-STATE RELAYS

AND TIMERS • 95

11 SUMMARY REVIEW OF UNITS 5–10 • 109

12 THE THREE-PHASE AC INDUCTION MOTOR • 113

13 STARTING THREE-PHASE AC INDUCTION MOTORS • 139

14 CONTROLLERS FOR THREE-PHASE MOTORS • 159

15 SOLID-STATE STARTERS AND CONTROLS • 193

16 THE WOUND-ROTOR INDUCTION MOTOR • 217

17 THE SYNCHRONOUS MOTOR • 233

18 SUMMARY REVIEW OF UNITS 12–17 • 247

19 SINGLE-PHASE INDUCTION MOTORS • 257

20 SPECIAL MOTORS AND APPLICATIONS • 283

21 AC SERIES AND REPULSION MOTORS • 299

22 ENERGY-EFFICIENT MOTORS • 317

23 THREE-PHASE MOTOR INSTALLATIONS • 329

24 SINGLE-PHASE MOTOR AND DC MOTOR INSTALLATION

AND THE NATIONAL ELECTRICAL CODE ® • 347

25 MOTOR MAINTENANCE • 355

LV Motor Starting & Protection

Low Voltage (LV) motor starting and protection is crucial for ensuring the reliable operation and longevity of electric motors used in industrial, commercial, and residential applications. LV motors, typically rated below 1000 volts, are widely used to drive equipment such as pumps, fans, conveyors, compressors, and mixers. Proper starting methods and protection systems are necessary to prevent electrical and mechanical stress, reduce energy consumption, and protect against faults.

1. Motor Starting Methods

Starting an LV motor directly from the power supply can result in a high inrush current, typically 6-8 times the motor’s rated current. This surge can cause mechanical stress and voltage drops in the power system. To mitigate these issues, various starting methods are employed:

a. Direct-On-Line (DOL) Starter

- Description: The simplest and most common method, where the motor is directly connected to the power supply.

- Advantages:

- Simple and cost-effective.

- Suitable for small motors with low starting torque requirements (typically below 5 kW).

- Disadvantages:

- High inrush current can cause voltage dips.

- Mechanical stress on motor components.

- Applications: Small pumps, fans, and compressors.

b. Star-Delta Starter

- Description: The motor initially starts in a star (wye) configuration, reducing the voltage applied to each phase. After a short period, it switches to a delta configuration for normal operation.

- Advantages:

- Reduces starting current by approximately one-third.

- Minimizes voltage drop in the supply network.

- Disadvantages:

- Lower starting torque.

- Requires additional wiring and a more complex starter panel.

- Applications: Medium-sized motors, such as pumps, conveyors, and compressors.

c. Soft Starter

- Description: A soft starter uses solid-state devices to gradually increase the motor voltage, providing a smooth ramp-up during startup.

- Advantages:

- Smooth acceleration reduces mechanical stress.

- Adjustable starting current and torque.

- Prevents sudden voltage drops in the power system.

- Disadvantages:

- Higher cost compared to DOL and star-delta starters.

- Limited speed control during normal operation.

- Applications: Applications with high starting torque requirements, such as blowers, mixers, and large pumps.

d. Variable Frequency Drive (VFD)

- Description: A VFD controls the frequency and voltage supplied to the motor, enabling precise speed and torque control during startup and operation.

- Advantages:

- Provides smooth starting with low inrush current.

- Offers full speed control and energy savings during operation.

- Reduces mechanical wear and extends motor life.

- Disadvantages:

- Higher initial cost and more complex setup.

- May introduce harmonics into the power system.

- Applications: Applications requiring variable speed control, such as fans, pumps, and conveyors.

e. Auto-Transformer Starter

- Description: An auto-transformer starter uses an auto-transformer to reduce the voltage during startup, lowering the inrush current.

- Advantages:

- Effective in reducing starting current and torque.

- Offers a range of voltage tapping options for different starting conditions.

- Disadvantages:

- More expensive than DOL and star-delta starters.

- Requires additional space for the transformer.

- Applications: Large motors where high starting torque is needed, such as crushers and heavy-duty compressors.

2. Motor Protection Systems

Protection systems are essential for safeguarding LV motors against electrical faults, mechanical failures, and environmental conditions that could lead to damage or failure. Key protection methods include:

a. Overload Protection

- Description: Protects the motor from sustained overcurrent conditions caused by excessive load or mechanical binding.

- Devices Used:

- Thermal Overload Relays: Use bimetallic strips that bend when overheated, breaking the circuit.

- Electronic Overload Relays: Provide more accurate protection by monitoring motor current electronically.

- Applications: Used in almost all motor starters, including DOL, star-delta, and soft starters.

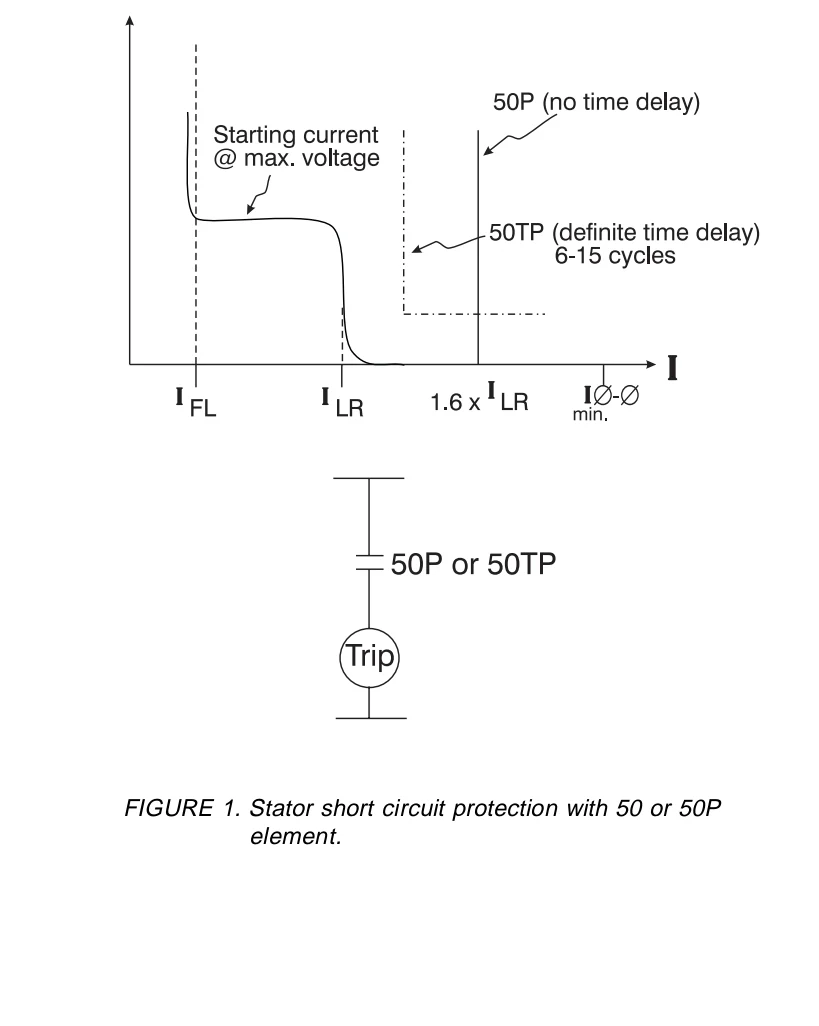

b. Short-Circuit Protection

- Description: Protects the motor and wiring from damage caused by short circuits, which result in very high currents.

- Devices Used:

- Circuit Breakers: Automatically disconnect the power supply when a short circuit is detected.

- Fuses: Melt and disconnect the circuit in case of excessive current flow.

- Applications: Essential in all motor installations, providing primary protection against short circuits.

c. Phase Loss and Phase Imbalance Protection

- Description: Protects the motor from phase loss (single-phasing) or significant imbalance between the phase currents, which can cause overheating.

- Devices Used:

- Phase Failure Relays: Monitor the voltage in each phase and disconnect the motor in case of phase loss or imbalance.

- Applications: Critical for three-phase motors in industrial applications.

d. Ground Fault Protection

- Description: Detects current leakage to ground, which can indicate insulation failure or a fault in the motor windings.

- Devices Used:

- Ground Fault Relays: Sense leakage currents and trip the circuit if a fault is detected.

- Residual Current Devices (RCDs): Provide protection against electric shock and fire by disconnecting the circuit during ground faults.

- Applications: Used in environments with high moisture or risk of insulation degradation.

e. Thermal Protection

- Description: Monitors the temperature of the motor windings to prevent overheating, which can cause insulation failure.

- Devices Used:

- Thermistors: Temperature-sensitive resistors embedded in the motor windings.

- Thermal Relays: Disconnect the motor when the temperature exceeds safe limits.

- Applications: Used in critical applications where overheating can lead to severe damage or safety hazards.

3. Best Practices for Motor Starting and Protection

a. Proper Sizing of Motor Starters and Protection Devices

- It is essential to select motor starters and protection devices based on the motor’s rating, application requirements, and operating conditions. Oversized or undersized components can lead to inefficiency or insufficient protection.

b. Regular Maintenance and Testing

- Routine inspections, testing of protection devices, and maintenance of starter components are vital to ensure reliable operation. Periodic testing of overload relays, circuit breakers, and thermal sensors helps in early detection of potential issues.

c. Monitoring and Diagnostics

- Advanced monitoring systems provide real-time data on motor performance, allowing for proactive maintenance. Using sensors and smart relays, technicians can detect abnormalities like voltage imbalance, high temperatures, or unusual vibrations.

d. Use of Surge Protection

- Motors are vulnerable to voltage surges caused by switching operations or lightning strikes. Surge protection devices help safeguard the motor’s insulation and prevent damage due to transient voltage spikes.

4. Conclusion

Proper starting and protection of LV motors are critical to ensuring efficient, reliable, and safe operation in various applications. By selecting the appropriate starting method and implementing comprehensive protection systems, operators can minimize the risk of motor failure, reduce maintenance costs, and extend the lifespan of their equipment. Advanced technologies like VFDs and smart monitoring systems offer enhanced control and diagnostics, making them indispensable in modern industrial automation.

For detailed technical resources and guidelines on LV motor starting and protection, consider exploring Electrical 4 Learning, which offers valuable handbooks and tutorials for electrical engineers and professionals.

"Download"LV Motor Starting & Protection

1. INTRODUCTION

Motor Protection: Application Considerations

Motor protection is a critical aspect of ensuring the safe, reliable, and efficient operation of electric motors. Effective protection minimizes downtime, reduces maintenance costs, and prolongs motor lifespan. When selecting and implementing motor protection devices, engineers must consider various factors such as motor type, application, load characteristics, and environmental conditions.

Key Motor Protection Considerations

Overload Protection

- Overloads occur when a motor draws more current than its rated capacity for an extended period, leading to excessive heat generation. This can damage the motor windings, insulation, and bearings.

- Overload relays are commonly used to detect overload conditions. There are two main types:

- Thermal Overload Relays: Use bimetallic strips that bend due to heat, triggering a trip when the motor current exceeds the set limit.

- Electronic Overload Relays: Provide more precise protection by continuously monitoring the motor current and using adjustable settings for different motor characteristics.

- Setting the correct overload trip point is crucial. Typically, it is set between 110% to 125% of the motor's full-load current rating to provide effective protection without nuisance tripping.

Short-Circuit Protection

- Short circuits can cause a sudden surge in current, potentially damaging the motor, wiring, and connected equipment. This could be due to insulation failure, wiring faults, or mechanical damage.

- Fuses and circuit breakers are the primary devices used for short-circuit protection:

- Fuses provide fast-acting protection by melting and disconnecting the circuit when current exceeds the rated value.

- Circuit Breakers can be reset after a trip and provide both short-circuit and overload protection. Molded Case Circuit Breakers (MCCBs) and Motor Protection Circuit Breakers (MPCBs) are commonly used in motor circuits.

Phase Failure and Phase Imbalance Protection

- Phase failure (single phasing) occurs when one of the supply phases is lost. This can cause severe damage to three-phase motors, as the remaining phases draw higher currents to compensate, leading to overheating.

- Phase imbalance happens when the voltage or current in one or more phases deviates significantly from the others. An imbalance greater than 5% can reduce motor efficiency and cause excessive heating.

- Phase monitoring relays detect phase failure and imbalance, disconnecting the motor from the supply to prevent damage. These relays continuously monitor the voltage levels and ensure proper phase sequence.

Ground Fault Protection

- Ground faults occur when there is an unintended connection between a phase conductor and the ground, resulting in dangerous currents that can cause electrical shock hazards, equipment damage, and fire risks.

- Ground fault relays detect low-level faults by monitoring leakage currents and disconnecting the motor when a fault is detected. They offer more sensitive protection than traditional fuses or breakers, especially for low-level faults that may not cause immediate high currents.

- Using Ground Fault Circuit Interrupters (GFCIs) or Residual Current Devices (RCDs) provides additional safety by detecting even small leakage currents and protecting personnel from electrical shock.

Overtemperature Protection

- Excessive motor temperature is a common cause of motor failure, often resulting from overloading, inadequate cooling, or high ambient temperatures. High temperatures degrade insulation, reducing motor life.

- Thermal sensors such as thermistors, RTDs (Resistance Temperature Detectors), and thermocouples are installed in the motor windings or bearings to monitor temperature.

- These sensors are connected to a protection relay or motor controller that trips the motor when the temperature exceeds a safe threshold, preventing thermal damage.

Undervoltage and Overvoltage Protection

- Undervoltage occurs when the supply voltage drops below the motor's rated voltage, causing increased current draw, reduced torque, and potential overheating.

- Overvoltage can lead to excessive currents, insulation breakdown, and damage to the motor windings.

- Voltage monitoring relays detect abnormal voltage levels and disconnect the motor to prevent damage. They ensure that the motor operates within a specified voltage range, usually ±10% of the rated voltage.

Locked Rotor Protection

- Locked rotor conditions happen when the motor's rotor is unable to rotate while the motor is energized, causing a surge in current that can lead to overheating and damage.

- Instantaneous trip relays or locked rotor relays detect high inrush currents associated with a locked rotor condition and quickly disconnect the motor to prevent damage.

- This protection is crucial in applications where the motor drives mechanical loads like pumps, compressors, or conveyors that may become jammed.

Environmental Considerations

- Motors operating in harsh environments require additional protection against factors such as moisture, dust, corrosive gases, and extreme temperatures. This can be achieved through:

- Ingress Protection (IP) Ratings: Selecting motors with appropriate IP ratings (e.g., IP55, IP66) to safeguard against dust and water ingress.

- Enclosures: Using protective enclosures like TEFC (Totally Enclosed Fan Cooled) or TENV (Totally Enclosed Non-Ventilated) to shield the motor from environmental contaminants.

- Corrosion Protection: Applying special coatings or using stainless steel components in corrosive environments.

- Motors operating in harsh environments require additional protection against factors such as moisture, dust, corrosive gases, and extreme temperatures. This can be achieved through:

Vibration Monitoring

- Excessive vibration can indicate mechanical problems such as misalignment, unbalanced loads, or bearing failures. Prolonged vibration can lead to mechanical damage and reduce motor life.

- Vibration sensors or accelerometers are used to monitor vibration levels. When excessive vibration is detected, the motor is shut down to prevent further damage.

- Regular alignment checks and balancing of rotating components help minimize vibration issues.

Motor Starting Considerations

- The starting method used can influence the protection requirements for the motor. For example:

- Direct-On-Line (DOL) Starters may require enhanced short-circuit protection due to the high inrush current.

- Star-Delta Starters and Soft Starters reduce the starting current, decreasing the stress on protection devices and the motor.

- Variable Frequency Drives (VFDs) offer integrated protection features like overcurrent, overvoltage, undervoltage, and phase loss protection.

- The starting method used can influence the protection requirements for the motor. For example:

Integration with Motor Management Systems

- Modern motor protection systems often integrate with Motor Management Systems (MMS), providing comprehensive monitoring, control, and diagnostics capabilities. These systems use sensors and controllers to monitor various parameters like voltage, current, temperature, and vibration in real-time.

- The data collected can be analyzed to predict potential failures, enabling predictive maintenance strategies and reducing unexpected downtime.

Conclusion

Effective motor protection is essential for maximizing motor performance, extending equipment lifespan, and ensuring operational safety. By considering factors such as load type, operating environment, voltage quality, and starting methods, engineers can design a robust protection system that addresses potential risks and minimizes the likelihood of motor failures.

For detailed resources and practical guides on motor protection, platforms like Electrical 4 Learning offer valuable handbooks and information tailored to both beginners and experienced professionals. This ensures that users can select, install, and maintain motor protection devices effectively, optimizing the reliability and efficiency of their motor systems.

"Download" Motor Protection Application Considerations

Energy-Efficient Electric Motor Systems

Energy-efficient electric motor systems are designed to minimize energy consumption while maintaining or improving performance in various industrial and commercial applications. Given that electric motors account for nearly 45% of global electricity use, particularly in industries like manufacturing, HVAC, and transportation, optimizing their efficiency can lead to significant energy savings, reduced operational costs, and lower carbon emissions.

Key Components of Energy-Efficient Motor Systems

High-Efficiency Motors

- Energy-efficient motors are built to meet or exceed international standards such as IE3 and IE4, which define efficiency levels based on the International Electrotechnical Commission (IEC) framework. These motors are designed with enhanced materials, improved winding techniques, and optimized design to reduce energy losses from heat, friction, and electrical resistance.

- Premium Efficiency Motors (IE3) and Super Premium Efficiency Motors (IE4) offer substantial reductions in power losses compared to standard efficiency motors (IE1 and IE2). For instance, an IE4 motor can save up to 10% more energy than an IE1 motor of the same rating.

Variable Frequency Drives (VFDs)

- Variable Frequency Drives (VFDs) are a key component in energy-efficient motor systems. They control the speed and torque of the motor by adjusting the frequency and voltage of the power supplied. By matching motor speed to the actual load requirements, VFDs can significantly reduce energy consumption, particularly in applications with variable loads like pumps, fans, and conveyors.

- VFDs help minimize wasted energy during motor startup by providing a smooth ramp-up, reducing inrush current, and avoiding mechanical stress. They also contribute to extending motor lifespan by reducing wear and tear.

Power Quality and Motor Control Systems

- Improving power quality is crucial for enhancing motor efficiency. Power quality issues such as voltage imbalance, harmonics, and low power factor can cause motors to operate inefficiently. Using power factor correction (PFC) capacitors, harmonic filters, and balanced power supplies can help maintain optimal operating conditions.

- Advanced motor control systems with soft starters, programmable logic controllers (PLCs), and energy management systems further enhance efficiency by optimizing motor operation, reducing downtime, and enabling precise control over motor performance.

Efficient Motor Design and Materials

- The design and construction of energy-efficient motors focus on minimizing energy losses through various enhancements, including:

- Improved Stator and Rotor Designs: Reducing air gaps and optimizing lamination to lower core losses.

- High-Quality Bearings: Reducing friction and enhancing mechanical efficiency.

- Copper Windings: Using copper instead of aluminum in windings to lower electrical resistance and reduce losses.

- Advanced Insulation Materials: Enhancing thermal performance and reducing heat buildup, which contributes to energy loss.

- The design and construction of energy-efficient motors focus on minimizing energy losses through various enhancements, including:

Benefits of Energy-Efficient Motor Systems

Energy Savings

- The most significant benefit of energy-efficient motors is the reduction in energy consumption. On average, upgrading to a high-efficiency motor can result in energy savings of 15-25% compared to older, less efficient models. This reduction translates directly into lower electricity bills, especially in applications where motors run for extended periods.

Reduced Operating Costs

- Although energy-efficient motors often have a higher upfront cost than standard motors, the payback period is usually short due to energy savings. Over the motor's lifetime, lower energy consumption results in substantial cost savings, offsetting the initial investment.

Extended Motor Lifespan

- High-efficiency motors generate less heat and experience reduced wear and tear, leading to a longer lifespan. This reliability reduces the need for frequent maintenance, resulting in lower downtime and repair costs.

Lower Greenhouse Gas Emissions

- By consuming less energy, energy-efficient motors contribute to reducing the overall carbon footprint. Given that a large portion of electricity is still generated from fossil fuels, decreasing energy usage directly correlates with lower greenhouse gas emissions, supporting sustainability goals.

Compliance with Energy Standards and Regulations

- Many countries have implemented regulations and incentives to promote the use of energy-efficient motors. Standards like IEC 60034-30, NEMA Premium Efficiency, and EU Ecodesign Directive set minimum efficiency requirements for motors. Adopting high-efficiency motor systems helps organizations comply with these regulations, avoid penalties, and qualify for energy rebates and incentives.

Applications of Energy-Efficient Motor Systems

Energy-efficient motor systems are employed in a wide range of industries and applications, including:

- HVAC Systems: High-efficiency motors in fans, blowers, and pumps reduce energy use in heating, ventilation, and air conditioning systems, leading to lower operational costs.

- Industrial Manufacturing: In applications like conveyor systems, compressors, mixers, and grinders, energy-efficient motors help minimize power consumption and improve productivity.

- Water and Wastewater Treatment: Pumps with high-efficiency motors and VFDs ensure optimal water flow while reducing energy use, crucial in utility operations.

- Agriculture: Energy-efficient motors in irrigation systems, grain dryers, and feed systems help farmers reduce energy costs while improving reliability.

- Building Automation: Using VFDs and high-efficiency motors in elevators, escalators, and building management systems enhances overall energy performance.

Strategies for Improving Motor System Efficiency

Regular Maintenance and Monitoring

- Scheduled maintenance, such as lubrication, cleaning, and alignment, helps maintain motor efficiency by preventing issues like overheating, bearing failure, and winding insulation degradation. Implementing predictive maintenance using sensors and data analytics can further enhance efficiency by identifying potential problems before they lead to failures.

Upgrading Legacy Motors

- Replacing old, inefficient motors with modern, high-efficiency models is a direct way to improve energy efficiency. In cases where replacing the entire motor is not feasible, upgrading components such as adding VFDs or improving the power factor can still yield significant savings.

Optimizing Load and Usage

- Motors should be properly sized for their application to avoid operating at low efficiency. Oversized motors often operate at less than optimal load, wasting energy. Proper load management and load optimization techniques can ensure that motors run at their most efficient points.

Implementing Energy Audits

- Conducting regular energy audits helps identify areas where energy losses occur and where improvements can be made. These audits provide actionable insights for upgrading equipment, optimizing motor control settings, and implementing energy-saving measures.

Conclusion

Investing in energy-efficient electric motor systems is one of the most effective strategies for reducing industrial energy consumption and operational costs. By upgrading to high-efficiency motors, integrating VFDs, improving power quality, and implementing effective maintenance practices, businesses can achieve significant energy savings, enhance reliability, and contribute to environmental sustainability.

For more in-depth resources on energy-efficient motor systems, free handbooks and guides are available on platforms like Electrical 4 Learning, offering valuable insights and practical knowledge for electrical engineers and industry professionals.

"Download"Energy Efficient Electric Motors Systems

FOREWORD

Soft Starter Handbook: A Comprehensive Guide

The Soft Starter Handbook is a specialized resource designed to provide an in-depth understanding of soft starters, a crucial component in motor control systems. This handbook is an essential reference for electrical engineers, technicians, and professionals working with electric motors, especially in industries where controlling motor startup is critical for both efficiency and equipment longevity.

Key Contents of the Soft Starter Handbook

Introduction to Soft Starters

- The handbook begins with an overview of soft starters, defining their role and importance in motor control systems. A soft starter is an electronic device used to smoothly ramp up the voltage supply to an electric motor, reducing the inrush current and torque during startup. This helps prevent mechanical stress on the motor and connected equipment, enhancing system reliability.

Working Principle of Soft Starters

- The fundamental working principle of a soft starter is based on thyristors (SCRs) that control the voltage supplied to the motor. By gradually increasing the voltage, the motor starts slowly, reducing the initial high starting current and limiting mechanical stress. The handbook explains the operation step by step:

- Ramp-Up Period: The soft starter increases the voltage from a lower value to full voltage over a set period.

- Full Voltage Operation: After the motor reaches its full speed, the soft starter switches to bypass mode to minimize energy losses.

- Ramp-Down Period (if available): In some models, the soft starter also provides a controlled deceleration phase.

- The fundamental working principle of a soft starter is based on thyristors (SCRs) that control the voltage supplied to the motor. By gradually increasing the voltage, the motor starts slowly, reducing the initial high starting current and limiting mechanical stress. The handbook explains the operation step by step:

Benefits of Using Soft Starters

- The handbook outlines the primary advantages of using soft starters:

- Reduced Mechanical Stress: Limits wear and tear on mechanical components like couplings, belts, and gears.

- Lower Starting Current: Minimizes voltage dips in the power supply system, reducing the risk of tripping circuit breakers and protecting other equipment.

- Enhanced System Reliability: Decreases the risk of overheating and electrical damage to the motor.

- Energy Savings: Although not as efficient as Variable Frequency Drives (VFDs) in dynamic speed control, soft starters contribute to energy savings during startup and reduce peak demand charges.

- The handbook outlines the primary advantages of using soft starters:

Types of Soft Starters

- Soft starters are available in different configurations to suit various applications:

- Analog Soft Starters: Basic models with manual adjustments for ramp-up time and initial voltage settings.

- Digital Soft Starters: Advanced models with microprocessor controls, offering more precise adjustments, diagnostics, and communication features.

- Integrated Soft Starters: Built into motor control centers or other motor control devices for seamless integration in industrial systems.

- Soft starters are available in different configurations to suit various applications:

Applications of Soft Starters

- Soft starters are widely used in applications where a smooth start is essential to avoid mechanical stress or where frequent motor startups could lead to excessive wear and high maintenance costs. Common applications include:

- Pumps: Reducing water hammer effects in centrifugal pumps.

- Fans and Blowers: Preventing sudden surges that can damage ductwork or equipment.

- Conveyors: Avoiding abrupt starts that could cause product spillage or belt damage.

- Compressors: Minimizing mechanical shocks that could lead to premature bearing wear.

- Soft starters are widely used in applications where a smooth start is essential to avoid mechanical stress or where frequent motor startups could lead to excessive wear and high maintenance costs. Common applications include:

Comparison with Other Motor Starting Methods

- The handbook provides a comparative analysis between soft starters and other motor starting methods:

- Direct-On-Line (DOL) Starter: High inrush current and mechanical stress but simple and low-cost.

- Star-Delta Starter: Reduces starting current but requires more complex wiring and is less effective for low-torque loads.

- Variable Frequency Drives (VFDs): Offers full-speed control but is more expensive and complex than soft starters.

- This comparison helps users determine the best starting method based on application requirements, cost, and desired performance.

- The handbook provides a comparative analysis between soft starters and other motor starting methods:

Selection Criteria for Soft Starters

- The guide includes detailed information on selecting the appropriate soft starter for a given application. Factors considered include:

- Motor Power and Voltage Rating: Ensuring the soft starter can handle the motor's power requirements.

- Load Type: Analyzing whether the load is constant or variable, affecting the ramp-up profile needed.

- Environmental Conditions: Assessing ambient temperature, humidity, and potential exposure to dust or corrosive substances.

- Control Features: Evaluating the need for features like built-in bypass contactors, communication options, or overload protection.

- The guide includes detailed information on selecting the appropriate soft starter for a given application. Factors considered include:

Installation and Wiring

- Proper installation and wiring are crucial for the effective operation of a soft starter. The handbook provides step-by-step guidelines on:

- Mounting the Soft Starter: Ensuring adequate ventilation and proper placement to avoid overheating.

- Electrical Connections: Wiring diagrams for integrating the soft starter with the motor, power supply, and control system.

- Bypass Contactor Setup: Recommendations on using an external bypass contactor to reduce energy losses when the motor reaches full speed.

- Proper installation and wiring are crucial for the effective operation of a soft starter. The handbook provides step-by-step guidelines on:

Programming and Configuration

- Most modern soft starters allow for programming and fine-tuning of parameters such as:

- Ramp-Up and Ramp-Down Time: Adjusting the acceleration and deceleration period to match the application needs.

- Initial Voltage Setting: Setting the initial voltage level for a smoother start.

- Current Limit: Configuring the maximum starting current to prevent excessive power draw.

- The handbook includes practical examples and configuration steps to help users set up their soft starters effectively.

- Most modern soft starters allow for programming and fine-tuning of parameters such as:

Troubleshooting and Maintenance

- Regular maintenance and timely troubleshooting are essential for the reliable operation of soft starters. The guide provides a list of common issues, such as:

- Overcurrent Faults: Caused by incorrect settings or load issues.

- Under-Voltage Alarms: Due to power supply problems or wiring faults.

- Overheating: Often related to inadequate ventilation or excessive cycling.

- It offers detailed troubleshooting steps and preventive maintenance tips to minimize downtime.

- Regular maintenance and timely troubleshooting are essential for the reliable operation of soft starters. The guide provides a list of common issues, such as:

Safety Considerations

- Safety is a key aspect covered in the handbook. It includes:

- Electrical Safety Guidelines: Adhering to standards such as IEC 60947 for low-voltage switchgear and NEMA regulations.

- Protection Features: Using overload protection, phase failure detection, and short-circuit protection to safeguard both the motor and soft starter.

- Safety is a key aspect covered in the handbook. It includes:

Conclusion

The Soft Starter Handbook is an indispensable guide for anyone involved in motor control and industrial automation. It provides comprehensive knowledge, from basic concepts to advanced applications, helping professionals optimize motor startup, enhance equipment reliability, and reduce operational costs. For free and detailed electrical engineering resources, the Electrical 4 Learning website offers an excellent collection of handbooks and guides.

This resource is essential for making informed decisions about selecting, installing, and maintaining soft starters in various industrial applications, ensuring smooth and efficient motor operations.

The Motor Guide: A Comprehensive Resource for Electric Motors

The Motor Guide is a valuable reference document often used by electrical engineers, maintenance personnel, and industry professionals to understand electric motors comprehensively. These guides are typically published by leading motor manufacturers or electrical engineering platforms and provide detailed information on different types of motors, their applications, selection criteria, maintenance, and energy efficiency.

Key Contents of The Motor Guide

Introduction to Electric Motors

- The guide usually starts with a basic overview of electric motors, their history, and their role in various industries. It explains fundamental concepts such as what an electric motor is, how it works, and why it is an essential part of mechanical and electrical systems.

Types of Electric Motors

- A significant section is dedicated to different types of electric motors. The most common types include:

- AC Motors: Induction motors (squirrel cage and slip ring) and synchronous motors.

- DC Motors: Series, shunt, and compound wound motors.

- Special Motors: Servo motors, stepper motors, brushless DC motors, and universal motors.

- This section also covers the operating principles of each motor type, construction details, and their specific applications in industries like manufacturing, automotive, HVAC, and robotics.

- A significant section is dedicated to different types of electric motors. The most common types include:

Motor Selection and Sizing

- The guide provides detailed instructions on how to select the right motor for a specific application. Factors such as load characteristics, speed requirements, starting torque, duty cycle, and environmental conditions are considered.

- Motor Sizing is critical to ensure optimal performance, efficiency, and lifespan of the motor. The guide usually includes formulas and charts to help engineers calculate the appropriate motor size based on the application’s needs.

Motor Performance and Efficiency

- Performance characteristics like torque-speed curves, power factor, efficiency, and service factor are discussed in detail. The guide explains how to interpret these characteristics and optimize motor performance.

- Given the increasing focus on energy efficiency, modern motor guides also cover energy-efficient motors and regulations such as IE2, IE3, and IE4 efficiency classes. It highlights the benefits of using high-efficiency motors, including energy savings, reduced carbon footprint, and compliance with international standards.

Motor Control Techniques

- The section on motor control discusses different control methods, including:

- Direct On-Line (DOL) Starter

- Star-Delta Starter

- Soft Starters

- Variable Frequency Drives (VFDs)

- It explains how these techniques help in starting, stopping, and speed control of motors, enhancing their operational flexibility and efficiency.

- The section on motor control discusses different control methods, including:

Maintenance and Troubleshooting

- Maintenance is crucial for the reliable operation of electric motors. The guide typically outlines preventive maintenance practices, such as regular inspection, lubrication, vibration analysis, and temperature monitoring.

- A troubleshooting section provides a comprehensive list of common motor problems (e.g., overheating, vibration, noise, and insulation failure), their causes, and possible solutions. This helps engineers diagnose and fix issues quickly, minimizing downtime.

Installation and Safety

- Proper installation is vital to ensure the safe and efficient operation of motors. The guide offers best practices for installation, alignment, mounting, grounding, and wiring.

- Safety precautions related to handling, starting, and operating motors are also discussed. This section emphasizes compliance with safety standards like IEC, NEMA, and OSHA to prevent accidents and equipment damage.

Motor Standards and Regulations

- A comprehensive motor guide also includes information about international standards and regulations, including:

- IEC (International Electrotechnical Commission) Standards

- NEMA (National Electrical Manufacturers Association) Standards

- IEEE (Institute of Electrical and Electronics Engineers) Standards

- It discusses how these standards impact motor design, performance, and application in various industries.

- A comprehensive motor guide also includes information about international standards and regulations, including:

Case Studies and Applications

- Some guides include real-world case studies and application examples to demonstrate how specific motor types are chosen and utilized in various industries. This helps readers gain practical insights into selecting and using motors effectively.

Technical Data and Reference Charts

- The guide often includes an appendix with technical data, such as:

- Torque-speed curves

- Efficiency charts

- Power factor tables

- Motor dimension tables

- Wiring diagrams

- The guide often includes an appendix with technical data, such as:

Why Use The Motor Guide?

The Motor Guide serves as an essential tool for professionals involved in the design, selection, operation, and maintenance of electric motors. It helps in:

- Understanding Motor Technology: It offers a deep dive into the different motor types, their construction, and working principles.

- Optimizing Performance: With detailed information on control techniques and performance characteristics, users can optimize motor efficiency and reliability.

- Ensuring Compliance: It provides guidance on international standards and regulations, helping organizations ensure compliance with safety and efficiency requirements.

- Troubleshooting and Maintenance: Practical tips on maintenance and troubleshooting help prevent failures and prolong motor life.

Conclusion

The Motor Guide is a comprehensive resource that brings together all aspects of electric motors, from selection and installation to maintenance and troubleshooting. It is an indispensable tool for electrical engineers, technicians, and industry professionals, enabling them to make informed decisions, optimize motor performance, and ensure the safe and efficient operation of electric motors.

For a detailed handbook on electric motors, resources like the Electrical 4 Learning website offer excellent free materials tailored for both beginners and experienced engineers.

The Grundfos Motor Book is an authoritative guide created by Grundfos, a leading global manufacturer of pumps and water technology solutions. This handbook focuses on motors specifically designed for pump applications, offering in-depth knowledge about the design, operation, selection, and maintenance of electric motors for various pump types. As motors are critical components in pump systems, the book is an invaluable resource for engineers, technicians, and students looking to understand the electrical, mechanical, and operational requirements of motors used in fluid handling applications.

Key Topics Covered in the Grundfos Motor Book

Motor Fundamentals: The Grundfos Motor Book begins by explaining the basics of electric motors, covering how they work and the key principles that enable them to convert electrical energy into mechanical energy. It introduces common motor types, with an emphasis on those commonly paired with pumps, such as:

- Asynchronous (Induction) Motors: These are the most widely used type of motor for pumps due to their reliability and efficiency.

- Synchronous Motors: Often used in applications where precise speed control is essential.

- Permanent Magnet Motors: Increasingly popular due to their high efficiency, particularly in variable speed applications.

Motor Construction and Components: This section dives into the internal structure of a motor, explaining each component’s role, including the stator, rotor, bearings, windings, and cooling systems. Understanding the function and design of these parts is critical for selecting and maintaining a motor that operates efficiently in challenging environments like those with variable loads, high temperatures, or wet conditions.

Motor Performance Characteristics: Grundfos provides a detailed overview of motor performance factors, including:

- Torque: Essential for pump applications, torque is explained in terms of starting, running, and breakdown torque.

- Power and Efficiency: The book details how to calculate motor power and efficiency, helping users select motors that meet energy efficiency goals.

- Speed and Slip: These factors influence how well a motor meets pump requirements, particularly in centrifugal pump applications where speed control is vital.

- Thermal Management: Effective motor cooling is essential to prevent overheating and prolong motor life, and the book explains various cooling methods, including air and liquid cooling.

Motor Protection and Control: The handbook emphasizes the importance of protection systems to enhance motor safety and performance. It discusses:

- Overload and Overheat Protection: Protects the motor from conditions that can cause overheating and premature failure.

- Phase Protection: For three-phase motors, protection against phase imbalances or loss is essential.

- Soft Starters and Variable Frequency Drives (VFDs): Used to control motor speed, VFDs are particularly beneficial for pump applications that require variable flow rates, as they enable energy savings and reduce wear on the pump.

Application-Specific Motor Selection: Grundfos focuses on how to match motor characteristics with specific pump applications, such as:

- Centrifugal Pumps: These pumps require motors with specific torque characteristics that can handle varying load conditions.

- Submersible Pumps: Require motors with excellent sealing and cooling systems due to their operating environment.

- Positive Displacement Pumps: Need motors capable of handling constant torque at varying speeds.

Energy Efficiency and Standards: The book highlights the importance of selecting motors that comply with international energy efficiency standards, such as IE2, IE3, and IE4 efficiency classes. Grundfos explains how investing in higher-efficiency motors can result in long-term energy savings, reduced operational costs, and a lower environmental footprint.

Installation and Maintenance Guidelines: Proper installation and regular maintenance are essential to ensure optimal motor performance and longevity. Grundfos includes step-by-step guidance on motor alignment, mounting, and connections, along with tips for preventive maintenance and troubleshooting. Common issues such as bearing failures, noise, vibrations, and thermal overloads are covered, along with recommended solutions.

Advanced Topics: Smart Motor Technology: Grundfos discusses the impact of digital technologies, such as smart motors equipped with built-in sensors that monitor temperature, vibration, and power usage in real-time. Such technology allows for predictive maintenance, ensuring issues are identified and resolved before they lead to failure, which is particularly valuable in critical applications like water supply, wastewater treatment, and HVAC systems.

Who Can Benefit from the Grundfos Motor Book?

This handbook is a valuable resource for engineers, pump designers, technicians, facility managers, and students who work with motor-driven pump systems. It provides foundational knowledge for beginners and serves as a detailed technical reference for experienced professionals, offering insights that can lead to more efficient and reliable motor-pump installations.

Why the Grundfos Motor Book is a Key Resource

Grundfos, known for its innovative pump technology, brings together decades of expertise in this book. The detailed explanations, diagrams, and practical examples make complex motor concepts accessible, enabling readers to make informed choices in motor selection, system design, and maintenance. By following the book’s guidelines, users can enhance motor efficiency, prolong equipment life, and achieve reliable pump operation, which is crucial in energy-intensive industries like water treatment, agriculture, and industrial processing.

SECTION I

The L&T Motor Starter Handbook is a comprehensive guide developed by Larsen & Toubro (L&T) specifically for understanding and implementing motor starters in industrial and commercial applications. This handbook provides detailed information on various types of motor starters, including Direct-On-Line (DOL) starters, Star-Delta starters, and Soft Starters, as well as the protection systems and control mechanisms required to safely and efficiently operate motors.

Key Areas Covered in the Handbook

Motor Basics and Starter Types: The handbook begins with an overview of electric motors, describing different types (e.g., single-phase, three-phase) and their starting requirements. It explains the purpose of a motor starter—to safely start and stop a motor by controlling the inrush current, which is usually high when a motor first starts. The handbook then categorizes and explains the various types of starters, such as:

- Direct-On-Line (DOL) Starters: These are used for motors that can tolerate high starting current and are generally suitable for low-power motors.

- Star-Delta Starters: Suitable for larger motors, Star-Delta starters reduce the initial starting current by configuring the motor to start in a star configuration and then switch to a delta configuration.

- Soft Starters: These use solid-state devices to gradually ramp up the voltage, thereby providing a smooth start and reducing mechanical stress.

Protection Systems: L&T emphasizes the importance of protection for motors and associated equipment. The handbook covers various types of protection, including:

- Overload Protection: Protects the motor from excessive current due to overload conditions.

- Short-Circuit Protection: Prevents damage to the motor and starter components in the event of a short circuit.

- Phase Loss Protection: Ensures that the motor shuts down if there is a loss of one phase in a three-phase system, preventing damage from imbalanced loads.

Control Circuits and Wiring Diagrams: The handbook includes wiring diagrams and circuit designs that illustrate how to install and connect motor starters. It explains control circuit components, such as contactors, overload relays, and auxiliary contacts, and offers guidance on selecting the correct components based on the motor’s power requirements and application.

Selection Guidelines: To help users select the appropriate starter for their application, the handbook provides selection criteria based on motor type, load conditions, and operational requirements. L&T includes tables and charts with technical specifications, making it easier for engineers to determine the correct starter type, protection rating, and component compatibility.

Troubleshooting and Maintenance: Maintenance practices are essential for ensuring the longevity of motor starters, and the handbook provides guidance on regular inspections, testing procedures, and maintenance protocols. It also includes troubleshooting tips to help users identify common issues such as tripped starters, unusual noises, or overheating, along with step-by-step solutions.

Case Studies and Application Examples: L&T includes real-world applications and case studies to illustrate how their starters perform in different environments, such as manufacturing plants, HVAC systems, water treatment facilities, and more. These examples demonstrate the versatility of L&T motor starters and offer insights into best practices for installation and operation.

Who Can Benefit from the Handbook?

The L&T Motor Starter Handbook is designed for engineers, electricians, maintenance personnel, and students who need a practical understanding of motor starters. It serves as a valuable resource for both beginners and experienced professionals who want to expand their knowledge of motor starter applications, component selection, and system design.

Why the Handbook is Valuable

With the L&T Motor Starter Handbook, users gain access to a well-organized, reliable source of information backed by one of India’s most respected engineering companies. The detailed explanations, practical examples, and technical guidelines make this handbook an essential tool for anyone involved in motor installation and maintenance. By following the guidelines and recommendations, users can optimize motor performance, enhance safety, and reduce the risk of electrical faults.

TABLE OF CONTENTS

The AC Motor Selection and Application Guide is an essential resource designed to help engineers, technicians, and decision-makers in selecting the right AC motors for various applications. This guide provides a comprehensive overview of AC motor types, including induction, synchronous, and servo motors, while discussing each type’s unique characteristics, performance capabilities, and suitable applications.

One of the key features of this guide is its in-depth analysis of motor performance factors, such as speed, torque, efficiency, power requirements, and durability. It explains the critical considerations involved in selecting an AC motor, including load characteristics, operating conditions, and environmental factors, which can greatly impact the motor’s effectiveness and lifespan.

The guide also emphasizes energy efficiency and operational costs, offering insights into motor designs that maximize energy use, reduce waste, and lower operational expenses. It addresses how to select motors with the correct insulation, enclosure types, and materials for challenging environments, such as those with high moisture or corrosive agents.

In addition, this guide provides application-specific recommendations for a variety of industries, including manufacturing, HVAC, agriculture, and automation. It also includes guidance on motor installation, maintenance practices, and safety considerations to ensure optimal performance and longevity.

Overall, the AC Motor Selection and Application Guide is a practical tool for anyone involved in motor selection and application, providing clear criteria, technical explanations, and real-world insights to help make informed motor selection decisions.

AC (Alternating Current) motor selection and application involve understanding the specific requirements of a given system and choosing an appropriate motor that meets performance, efficiency, and operational demands. AC motors are commonly used in industrial, commercial, and residential applications due to their simplicity, durability, and efficiency.

Key Factors in AC Motor Selection

Load Requirements: Understanding the load's nature (e.g., constant, variable, or peak) is essential for selecting the right motor. Motors are typically selected based on their ability to handle the load without excessive stress or loss of efficiency. Common applications for AC motors include fans, pumps, conveyors, compressors, and more.

Motor Type:

- Induction Motors: These are the most widely used AC motors due to their robustness and simplicity. They are ideal for fixed-speed applications where high reliability is needed. Induction motors are further divided into single-phase and three-phase types, with three-phase motors generally used for heavy-duty applications.

- Synchronous Motors: These motors operate at a constant speed and are ideal for applications where speed control and precision are important, such as in robotics and industrial automation.

- Servo and Variable Speed Motors: For applications requiring precise control of speed and position, servo motors or motors designed for variable-speed drives are preferred.

Power and Efficiency: The motor's power rating (in horsepower or kilowatts) should match the power requirements of the application. Efficiency is critical, especially in continuous operation settings, as it impacts energy costs. High-efficiency motors may come with initial higher costs but provide savings in the long term.

Speed and Torque: Motors must be able to produce the necessary torque at the desired speed. Applications needing high starting torque (such as conveyors or compressors) require motors with suitable torque characteristics to avoid stalling or damage.

Environmental Factors: Environmental conditions, such as temperature, humidity, dust, or corrosive atmospheres, affect motor durability and performance. Special enclosures and materials can protect motors from harsh conditions, like those in washdown or explosive environments.

AC Motor Applications

AC motors are essential in various industries due to their adaptability and efficiency. They are frequently found in:

- Industrial Automation: For controlling machinery and equipment in factories.

- HVAC Systems: Used to drive fans, compressors, and pumps.

- Appliances and Tools: Common in devices like washing machines, drills, and blenders.

- Transportation and Logistics: Motors are used in elevators, conveyors, and material handling systems.

By selecting the appropriate AC motor, industries can optimize performance, reduce energy consumption, and ensure reliable operation across applications. Understanding application requirements, load conditions, and environmental factors is essential to choosing a motor that provides the best balance of cost, efficiency, and reliability.

The Electric Motor Repair - Third Edition by Robert Rosenberg is a widely recognized and comprehensive guide that serves as a valuable resource for both professionals and students in the field of electric motor maintenance and repair. This edition dives into the technical aspects of electric motor construction, common issues, and repair techniques. It covers various types of electric motors, including AC and DC motors, and discusses the components and mechanics involved in their operation.

One of the key strengths of Rosenberg's work is its practical approach, with clear instructions, illustrations, and diagrams that make complex processes easier to understand. The book emphasizes the identification of faults and provides detailed troubleshooting techniques to resolve issues effectively. It covers topics such as insulation, winding, and testing, and it includes valuable insights into safety practices for repair technicians.

In addition to repair techniques, the book also delves into motor theory, which provides readers with a fundamental understanding of how motors operate, helping them grasp why certain repairs are necessary. This third edition has been updated to include modern practices and technologies that reflect the advancements in motor technology.

Overall, Rosenberg's Electric Motor Repair remains a staple reference in the field of motor repair and electrical engineering, blending theory and practice in a way that’s both accessible and thorough.

Electric motor repair involves diagnosing, maintaining, and restoring the functionality of electric motors, which are critical in various industries, from manufacturing to transportation. These repairs help extend the life of motors, prevent costly replacements, and ensure optimal performance, which is essential for equipment reliability and operational efficiency.

Key Components in Electric Motor Repair

Diagnosis and Troubleshooting: The first step in motor repair is identifying the issue. Common problems include overheating, unusual noises, vibrations, power loss, and poor motor efficiency. Technicians use tools like multimeters, oscilloscopes, and insulation testers to evaluate electrical and mechanical faults.

Disassembly and Inspection: The motor is carefully disassembled to inspect individual components. Core parts inspected include the stator, rotor, windings, bearings, and insulation. This process can reveal signs of wear, corrosion, insulation breakdown, or mechanical damage.

Cleaning and Reconditioning: Dust, debris, and contaminants can affect motor performance. Components are thoroughly cleaned, and damaged insulation may be replaced or repaired. Reconditioning might include processes like varnishing, to improve insulation and protect windings.

Rewinding: If a motor winding is burned or damaged, rewinding may be necessary. This involves removing the old winding, cleaning the core, and installing new windings. Precision in rewinding is crucial, as poor alignment or tension can affect the motor's efficiency.

Bearing Replacement and Lubrication: Bearings reduce friction and support the motor’s rotating components. Worn or damaged bearings are replaced, and the appropriate lubrication is applied to ensure smooth operation and reduce wear.

Testing and Balancing: Once repaired, the motor undergoes tests to ensure all issues are resolved. Testing includes measuring insulation resistance, continuity, and checking for electrical balance. Balancing helps eliminate vibrations that could damage the motor or connected equipment.

Reassembly and Installation: The motor is carefully reassembled and may be reinstalled in its original location, where a final round of testing ensures it performs to specifications.

Importance of Electric Motor Repair

Regular maintenance and timely repair prevent downtime, extend motor life, and lower energy costs by maintaining efficiency. Motor repair services are cost-effective, environmentally friendly, and reduce the demand for new motors. Skilled technicians with the right tools and knowledge play a crucial role in keeping motors running smoothly.

Electric motor maintenance and troubleshooting are crucial practices that keep motors running efficiently, prolong their lifespan, and prevent costly downtime. Electric motors are essential components in various applications, from industrial machinery to household appliances, so effective maintenance and troubleshooting can significantly reduce the likelihood of operational failures.

Importance of Electric Motor Maintenance

Preventing Unplanned Downtime

- Regular maintenance prevents unexpected motor failures that could halt production or disrupt services. By identifying and addressing potential issues early, maintenance reduces unplanned downtime, which is essential in industrial environments where production schedules are critical.

Extending Motor Life

- Electric motors are substantial investments, especially in industrial settings. Proper maintenance, such as regular lubrication, cleaning, and inspections, helps extend motor life by preventing issues like overheating, wear, and bearing failure.

Improving Energy Efficiency

- Well-maintained motors operate more efficiently, consuming less power for the same output. Maintenance practices, such as aligning motor shafts, balancing loads, and keeping motor parts clean, ensure optimal performance and energy efficiency, reducing operational costs.

Ensuring Safety

- Faulty motors pose safety risks, including electrical shock, overheating, or even fires. Regular maintenance ensures motors are operating within safe parameters, keeping personnel and facilities safe.

Key Areas of Electric Motor Maintenance

Visual Inspection

- Regularly inspect motors for visible signs of wear, corrosion, or damage. Check for loose bolts, deteriorated insulation, worn seals, and any unusual noises or vibrations, which often indicate mechanical problems or misalignment.

Lubrication

- Bearings require lubrication to operate smoothly and reduce friction. Over-lubricating or under-lubricating bearings can cause them to overheat and fail, so it’s important to follow the manufacturer’s guidelines for lubrication intervals and quantity.

Electrical Testing

- Testing electrical components, such as windings and insulation resistance, helps detect issues like winding shorts, ground faults, or insulation breakdown. Instruments such as megohmmeters measure insulation resistance, while multimeters and clamp meters check voltage and current levels.

Temperature Monitoring

- Motors should operate within specific temperature limits; overheating often indicates overloading, poor ventilation, or winding issues. Temperature monitoring, either through sensors or infrared thermometers, can help spot potential problems early.

Vibration Analysis

- Excessive vibration is a common indicator of issues like misalignment, imbalanced loads, or bearing wear. Vibration analysis identifies abnormal patterns, helping detect these issues early to prevent severe damage.

Cleaning and Dust Control

- Dust, dirt, and debris can clog ventilation and lead to overheating. Regular cleaning of motor vents and enclosures prevents dirt buildup and keeps the motor well-ventilated.

Common Troubleshooting Steps for Electric Motors

Checking for Power Supply Issues

- Inspect the power supply to ensure the motor is receiving the correct voltage and frequency. A blown fuse, tripped breaker, or loose connections can lead to starting failures or intermittent operation.

Diagnosing Overheating Issues

- Overheating can result from several factors, including overloading, restricted ventilation, or poor lubrication. Verify that the motor is not overloaded, check airflow paths, and ensure that bearings are lubricated correctly.

Addressing Vibration and Noise

- Vibration and noise often point to mechanical issues like misalignment, imbalance, or bearing failure. Align the motor and load shafts, check for balanced rotor loads, and inspect bearings for wear.

Troubleshooting Bearing Problems

- Bearings that are noisy, overheated, or cause vibration should be inspected. Replace worn bearings and ensure proper lubrication. In some cases, misalignment or shaft imbalance can cause premature bearing wear.

Dealing with Starting Failures

- If a motor fails to start, inspect the starter, contactor, and wiring for loose connections or burnt contacts. Verify that the control circuit is operating correctly and that there’s no tripped overload protection.

Investigating Electrical Faults

- Electrical faults, such as short circuits or ground faults, are common in motor windings. Testing with a megohmmeter or other diagnostic tools can reveal faulty windings or insulation degradation. Rewinding or replacing the motor may be necessary in cases of severe electrical faults.

Preventive Maintenance Schedule

A well-structured preventive maintenance schedule is critical for reliable motor operation. Typically, preventive tasks are divided into daily, weekly, monthly, and annual intervals:

- Daily Tasks: Visual inspection, checking for unusual noise, vibration, or overheating.

- Weekly Tasks: Clean motor housing, check lubrication levels, and monitor operating temperatures.

- Monthly Tasks: Measure and record vibration levels, inspect power connections, and test insulation resistance.

- Annual Tasks: Conduct a complete motor inspection, including a thorough electrical test, cleaning, bearing replacement if needed, and alignment checks.

Conclusion

Electric motor maintenance and troubleshooting are essential for efficient and safe operations. By focusing on visual inspections, lubrication, electrical testing, and temperature monitoring, maintenance teams can proactively identify and fix potential issues. Consistent preventive maintenance minimizes downtime, reduces repair costs, and extends motor lifespan, making it an invaluable practice for industrial and commercial applications.