A Pump Energy Efficiency Calculation Tool is a specialized software or application used in the field of fluid mechanics and engineering to assess the energy efficiency of pumps and pumping systems. It helps determine how effectively pumps are converting electrical energy into hydraulic energy and is a valuable tool for optimizing system performance and reducing energy consumption. Here's an overview of how such a tool typically functions:

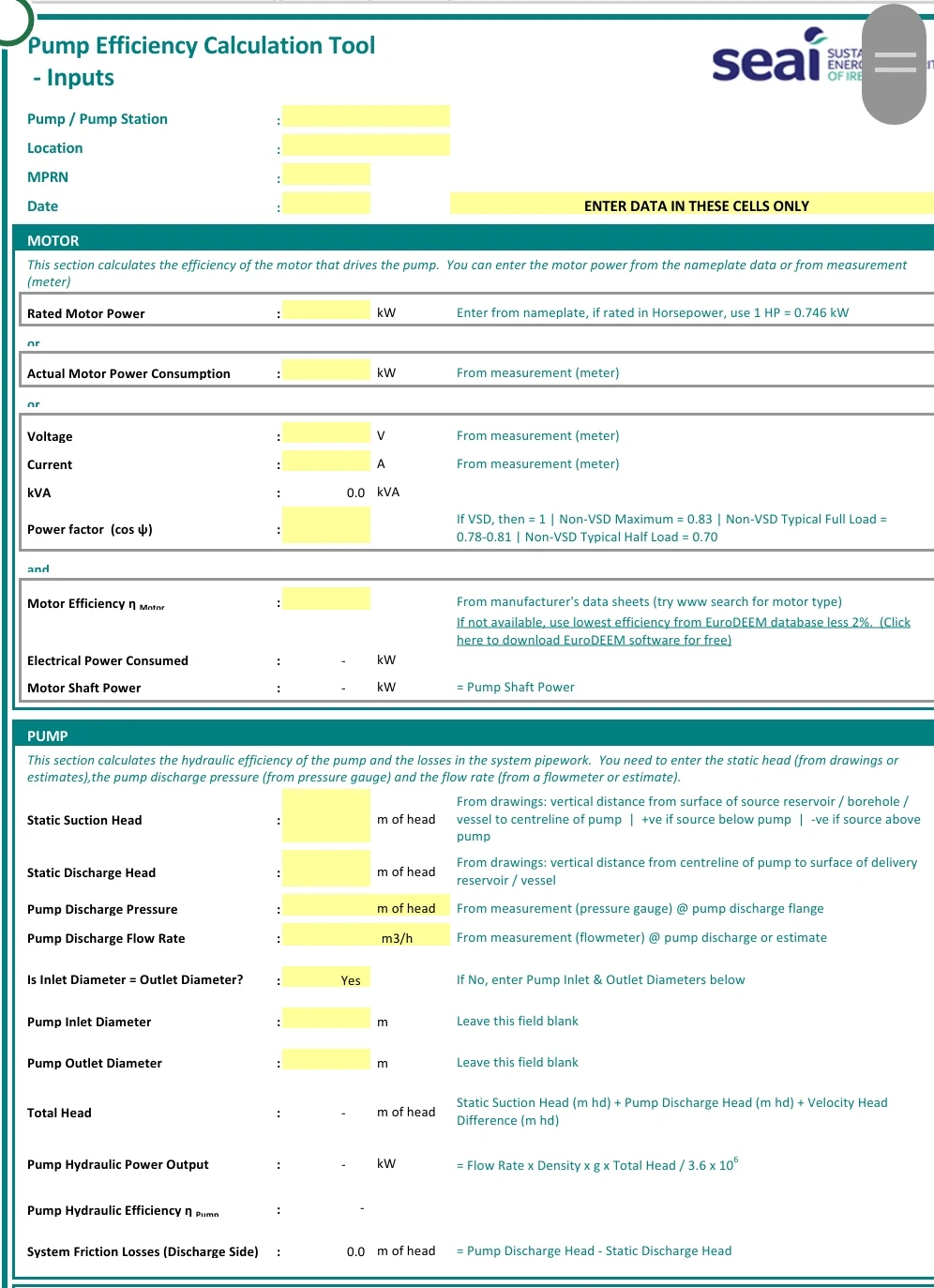

Input Parameters: Users input various parameters related to the pumping system. These include the type of pump (centrifugal, positive displacement, etc.), pump specifications (flow rate, head, efficiency), fluid properties, and operational details (such as the duty cycle and control methods).

Efficiency Calculation: The tool calculates the pump efficiency using known engineering formulas. This typically involves evaluating the hydraulic power output (work done by the pump) and the electrical power input (power supplied to the pump motor). Pump efficiency is a measure of how effectively the pump converts electrical energy into hydraulic energy.

Energy Consumption: The tool provides information on the energy consumption of the pump in terms of kilowatt-hours (kWh) or other relevant energy units. This helps users understand the cost and environmental impact of pump operation.

Comparative Analysis: Users can perform comparative analyses by inputting different scenarios or pump configurations. This can include testing the effects of different pump sizes, control strategies, or types of pumps on energy efficiency.

Recommendations: Some tools may offer recommendations for improving energy efficiency. For instance, it might suggest adjusting the operating speed, implementing variable frequency drives (VFDs), or selecting a different pump type to better match the system requirements.

Graphical Outputs: Many tools provide graphical representations of system performance, including pump curves, efficiency curves, and energy consumption trends. These visuals make it easier to understand and communicate the results.

Life Cycle Cost Analysis: In addition to immediate energy consumption, some tools can perform life cycle cost analysis. This helps users assess the long-term cost of operating and maintaining the pumping system, factoring in initial costs, energy costs, and maintenance expenses.

Compliance with Standards: The tool may provide information on how the pumping system aligns with industry standards and regulations related to energy efficiency. It can help users ensure compliance with relevant guidelines.

A Pump Energy Efficiency Calculation Tool is especially valuable in industries where pumps play a significant role, such as water treatment, HVAC, manufacturing, and agriculture. By optimizing pump efficiency, users can reduce energy costs, extend the lifespan of equipment, and minimize the environmental impact of their operations. These tools are essential for engineers, facility managers, and anyone involved in designing or maintaining pumping systems.