In manufacturing facilities, compressed air is so widely used that it is often regarded as the fourth utility after electricity, natural gas and water.

The tried and true pick-and-place method with horizontal and vertical travel and a gripper is probably one of the most common uses

But compared to electricity, compressed air is more expensive, so why is it so widely used to drive factory automation systems?

The main reasons are lower upfront and maintenance costs, which combine

to make pneumatics the most popular and cost-effective choice for executing mechanical motion. It’s hard to beat the simplicity and reliability of pneumatics.

Linear Power Transmission Options

Linear power transmission is typically done with fluid (pneumatic with air or hydraulic with oil) or electric power. In electric power systems,electromechanical devices such as belts, pulleys, chains, sprockets and clutches convert rotational motion from motors to linear force. The main exception is linear motors, a relatively expensive specialty technology used to move very light loads.

Although many vendors often promote the competing technology of their choice, the choice of power transmission depends on the application. It’s not uncommon for larger machines to have all three of the power transmission technologies in use simultaneously. But many other machines only use pneumatics due to some advantages over other power methods.

Linear Power Transmission Comparison

Table 1A below lists some of the general advantages associated with pneumatic, hydraulic and electrical means of producing linear mechanical motion.

Pneumatic systems are simpler than hydraulic and electric systems, conferring advantages in upfront costs and maintenance. Fluid power systems produce linear motion with simple pneumatic and hydraulic cylinders and actuators. Converting electrical to linear power often requires one or more mechanical devices to convert the motor rotation.

Pneumatic and hydraulic power transmission methods typically produce more power in a smaller space, so small pneumatic cylinders can be used to provide the high required clamping or positioning force needed to hold a product in certain machining and other applications.

Control of this power is usually easier with pneumatics and hydraulics than with electric systems. A simple valve, regulator and flow controls are usually all that’s needed to control cylinder direction, speed and force. An electric actuator often needs an electronic controller, multiple I/O points, communication cables, and possibly encoder feedback, along with more complex automation system programming.

A pneumatic actuator typically has two very repeatable end-of-travel positions which are set by using a hard stop, cushion or shock. Electric actuators are also very repeatable, and can be easily designed with multiple stop positions. With new advances in electronics, pneumatic control of multiple stop positions is also now possible although not as precise as electric can be. Whether it is end-of-stroke or multiple stop positions, both pneumatic and electrical actuators can attain the desired position at high speeds.

“Pneumatic hardware is also much simpler to design, and less expensive to purchase and install.”

Operation of a compressor may have additional costs compared to electric, but the availability of clean dry air in most facilities is common. In addition, pneumatic components often have the lowest maintenance costs, such as when replacing seals, or a whole cylinder for that matter, which is often much cheaper than servicing, let alone replacing, an electric actuator.

Noise is becoming less of a concern with fluid power devices. Designs have improved over the years, greatly reducing clatter to about the same level as a stepper-driven electric actuator. New improvements in designs and efficiency of compressors, and the standard use and distribution of clean dry air in a manufacturing facility, also make pneumatics a good choice for industrial automated machinery.

A Good Application for Pneumatics

Pneumatic power transmission methods are often the best way to move parts and tooling in industrial machines. These pneumatic systems perform a myriad of tasks in automated equipment such as clamping, gripping, positioning, lifting, pressing, shifting, sorting and stacking. Some adaptive uses—each of which could include closed loop control for more precise positioning—include tensioning, pressing, labeling, embossing, crimping and cutting.

A Good Application for Pneumatics

Pneumatic power transmission methods are often the best way to move parts and tooling in industrial machines. These pneumatic systems perform a myriad of tasks in automated equipment such as clamping, gripping, positioning, lifting, pressing, shifting, sorting and stacking.

Some adaptive uses—each of which could include closed loop control for more precise positioning—include tensioning, pressing, labeling, embossing, crimping and cutting.

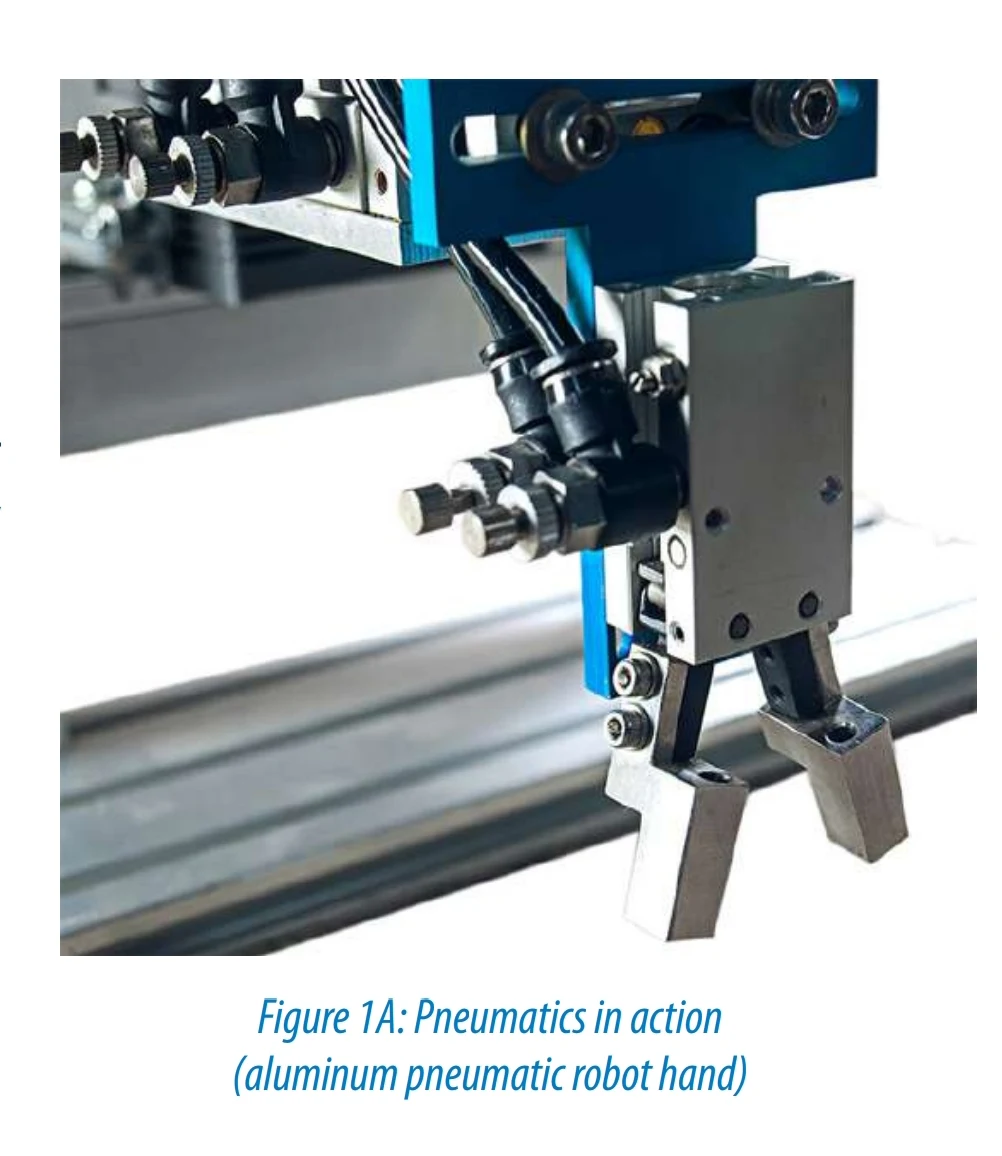

The tried and true pick-and-place method with horizontal and vertical travel and a gripper is probably one of the most common uses

of pneumatics. Clamping or part positioning functions are also widely implemented with pneumatics. If tooling needs to move, a part

needs to be held, or a force or tension needs to be applied, pneumatic systems can likely provide a solution.