1.______ maintenance is regular period planned maintenance which eliminates breakdowns and outages.

1.Routine

2.Preventive

3.Corrective

4.Operation

Answer (Detailed Solution Below)

Option 2 : Preventive

Preventive maintenance:

Preventive maintenance is a regular period planned maintenance which eliminates breakdowns and outages.

Preventive maintenance operates based on a schedule, where maintenance tasks are completed at specific intervals prior to downtime events. This is because the goal of preventive maintenance is to maximize the lifespan and runtime of equipment.

Preventive maintenance consists of:

Proper plans and installation of machine/equipment

Periodic inspection of the plant, equipment, and machines

Repetitive servicing, upkeep, and overhauling

Adequate lubrication, cleaning, and painting

2 With the increase in cost of preventive maintenance, the breakdown maintenance cost will ______.

1.Decreases

2.Increases at a faster rate

3.No change

4.Increases

Answer (Detailed Solution Below)

Option 1 : Decreases

Preventive maintenance identifies any issues before equipment failure or downtime, through routinely scheduled maintenance. While breakdown maintenance works by running equipment until it breaks down, in which case repairs and maintenance are performed.

So that with the increase in the cost of preventive maintenance, lifespan or runtime of equipment improved and equipment failure avoided. Hence need for breakdown maintenance reduced, which will reduce breakdown maintenance costs

3.Condition monitoring is the basis for _______ maintenance.

1.preventive

2.shutdown

3.breakdown

4.predictive

Answer (Detailed Solution Below)

Option 4 : predictive

Maintenance:

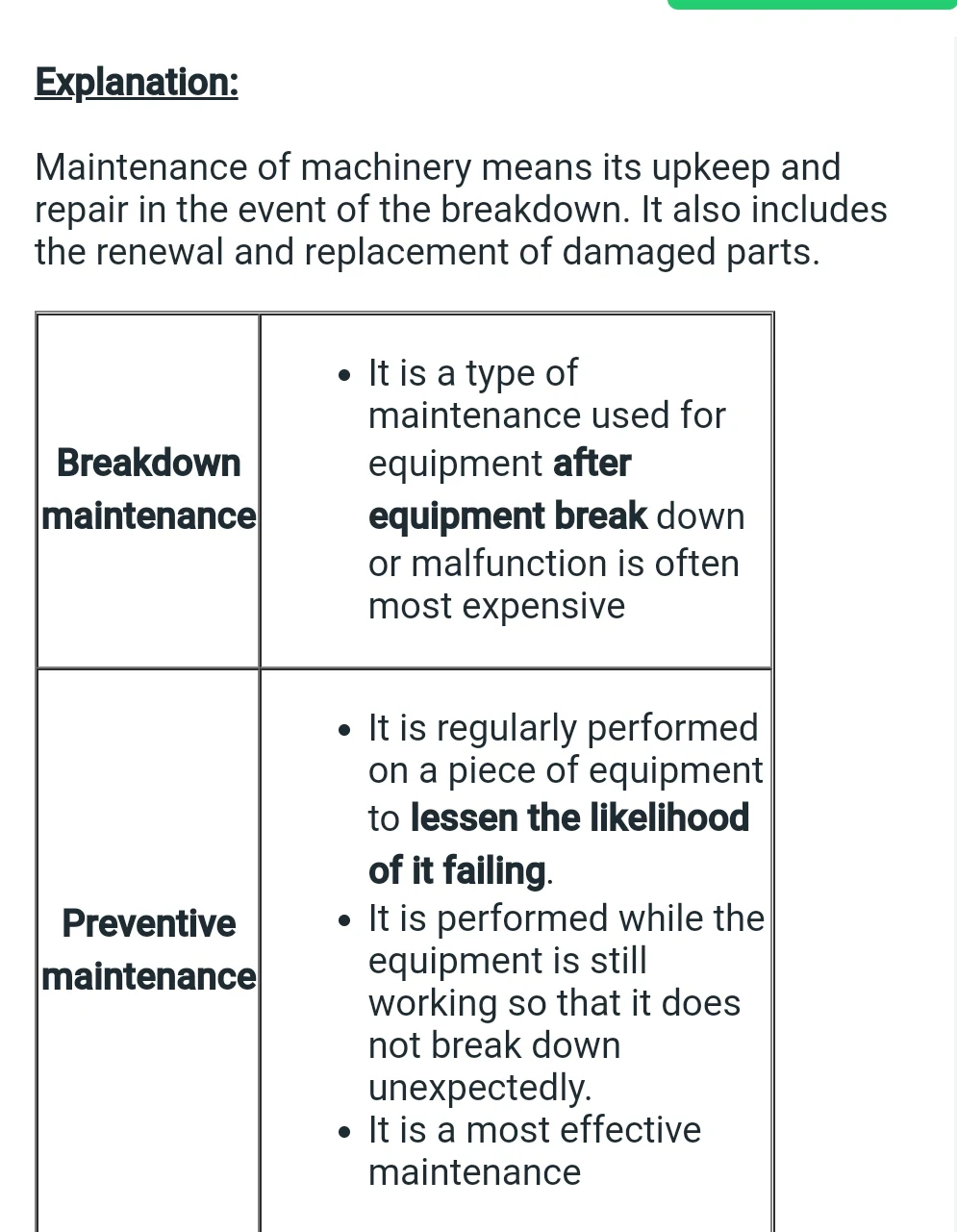

Maintenance of machinery means its upkeep and repair in the event of a breakdown.

It also includes the renewal and replacement of damaged parts.

Types of maintenance

4.Which statement describes a characteristic feature of routine preventive maintenance?

1.Maintenance schedule needs to be decided, based on maintenance requirements entered in the manual

2.Maintenance could be done either during the working of the machine or during shut interval down period

3.Maintenance done at irregular frequencies

4.Maintenance is performed only if the machine has a fault or defect

Answer (Detailed Solution Below)

Option 1 : Maintenance schedule needs to be decided, based on maintenance requirements entered in the manual

Maintenance of machinery means its upkeep and repair in the event of the breakdown. It also includes the renewal and replacement of damaged parts

Types of maintenance:

1.Breakdown maintenance/Corrective maintenance

2.Preventive maintenance

3.Predictive maintenance

Preventive maintenance: It is planned maintenance. It is maintenance that is regularly performed on a piece of equipment to lessen the likelihood of it failing. It is performed while the equipment is still working so that it does not break down unexpectedly.

Preventive maintenance consists of:

Maintenance schedule needs to be decided, based on maintenance requirements entered in the manual

*Proper plans and installation of machine/equipment

*Periodic inspection of the plant, equipment, and machines

*Repetitive servicing, upkeep, and overhauling

Adequate lubrication, cleaning, and painting

Additional Information

Breakdown maintenance

It is a type of maintenance used for equipment after equipment break down or malfunction is often the most expensive.

Predictive maintenance

It is first to predict when equipment failure might occur, and secondly, to prevent the occurrence of the failure by performing maintenance. Monitoring for future failure allows maintenance to be planned before the failure occurs.

5.What type of maintenance is most effective?

1.Shutdown Maintenance

2.Corrective Maintenance

3.Breakdown maintenance

4.Preventing Maintenance

Answer (Detailed Solution Below)

Option 4 : Preventing Maintenance